Introduction: Building Your Own Chicken Coop Raising chickens can be a rewarding experience, providing you with fresh eggs and natural pest control. However, before you bring your feathered friends home, you'll need a safe and comfortable place for them to live. Building your own chicken coop allows you to customize the design to suit your specific needs and space limitations. This guide provides a step-by-step process for constructing a simple yet functional chicken coop.

Planning and Design: Laying the Foundation for Success The first step in building your coop is careful planning. Consider the number of chickens you plan to keep. A general rule of thumb is 4 square feet of coop space per chicken and 8-10 square feet of run space per chicken. Sketch out a basic design, taking into account factors like ventilation, sunlight exposure, and predator protection. Decide on the dimensions and features you want to include, such as nesting boxes, roosting bars, and a secure door. Create a materials list based on your design. Common materials include lumber, plywood, hardware cloth, roofing materials, and fasteners.

Step 1: Building the Base Frame Begin by constructing the base frame. Cut your lumber according to your design plans. Assemble the frame using screws or nails, ensuring it is square and level. This frame will provide the foundation for your coop. If you plan to raise the coop off the ground (recommended for pest control and ventilation), attach legs or posts to the base frame. Treat the wood with a weather-resistant sealant or paint to protect it from the elements.

Step 2: Constructing the Walls Next, build the walls of the coop. Cut the lumber to the desired height and width of the walls. Frame out the walls using the same techniques as the base frame. Consider including windows for ventilation and sunlight. Attach plywood to the framed walls, creating solid panels. Cut openings for the door and windows before attaching the plywood. Ensure that all corners are square and that the walls are securely fastened to the base frame.

Step 3: Creating the Roof The roof is crucial for protecting your chickens from the weather. Decide on the type of roof you want (e.g., slanted, gable, or flat). Build a frame for the roof using lumber, similar to the walls and base. Cover the frame with plywood. Apply roofing materials such as asphalt shingles, metal roofing, or cedar shakes. Ensure the roof is watertight to prevent leaks and keep your chickens dry. Provide adequate overhangs to protect the walls from rain.

Step 4: Adding the Door and Windows Install the door and windows. Build a sturdy door frame and attach it to the opening in the wall. Construct a door from lumber and plywood, ensuring it is securely hinged and latched. If using windows, install them securely in their frames. Consider using hardware cloth or wire mesh over the windows to prevent predators from entering the coop. Make sure the door latches securely to keep predators out.

Step 5: Building the Nesting Boxes and Roosting Bars Nesting boxes provide a comfortable and private space for your chickens to lay eggs. Roosting bars give them a place to sleep off the ground, protecting them from drafts and predators. Construct nesting boxes from plywood or lumber and place them inside the coop. A good size for a nesting box is approximately 12x12x12 inches. Install roosting bars at varying heights, allowing your chickens to choose their preferred spot. Use round, smooth perches for comfort.

Step 6: Building the Run (Optional but Recommended) The run provides your chickens with an outdoor space to roam and forage. Build a frame for the run using lumber and cover it with hardware cloth or chicken wire. Ensure the run is securely attached to the coop and that the wire extends a few inches underground to prevent predators from digging under it. Include a door in the run for easy access. Consider covering part of the run to provide shade and protection from the rain.

Step 7: Finishing Touches and Safety Add any finishing touches, such as painting or staining the coop. Check for any sharp edges or gaps that could injure your chickens. Securely fasten all hardware and ensure that the coop is predator-proof. Provide fresh water and food for your chickens. Regularly clean the coop to prevent the buildup of droppings and maintain a healthy environment. Enjoy your newly built chicken coop and the fresh eggs it will provide.

List Of Free Online Tools For Front-end Web Development (updated 2020)

Free!: Photoset By Aoineko On Deviantart

Free

www.cristinacabal.com

www.cristinacabal.com ![Cedarshed studio 12x6 shed [st126]](https://i0.wp.com/www.shednation.com/oscthumb.php?src=/images/cedarshed/cedarshed-studio-shed-st96-1.jpg&w=1500&h=1220&f=jpg&q=95&hash=a1b196bdc5513eb64d7a831305149a4c) www.shednation.com ```html

www.shednation.com ```html  www.gazebocreations.com

www.gazebocreations.com  theshedshopusa.com

theshedshopusa.com  pngtree.com ```html

pngtree.com ```html  www.flickriver.com

www.flickriver.com  facts.net

facts.net  shedprojectplan.blogspot.com

shedprojectplan.blogspot.com  shedprojectplan.blogspot.com

shedprojectplan.blogspot.com  www.amazon.com

www.amazon.com  www.gazebocreations.com

www.gazebocreations.com  wallpapercave.com ```html

wallpapercave.com ```html  www.zastavki.com

www.zastavki.com  wallpapercave.com

wallpapercave.com  www.pexels.com ```html

www.pexels.com ```html  www.pinterest.cl

www.pinterest.cl :max_bytes(150000):strip_icc()/roof-168262250-crop-59a6e9a622fa3a0010aa3a27.jpg) www.thoughtco.com

www.thoughtco.com  shedplans.org

shedplans.org  shedplans.org

shedplans.org  shedplans.org

shedplans.org  infoupdate.org

infoupdate.org  www.pinterest.com

www.pinterest.com  okcredit.in

okcredit.in  www.customwheeloffset.com

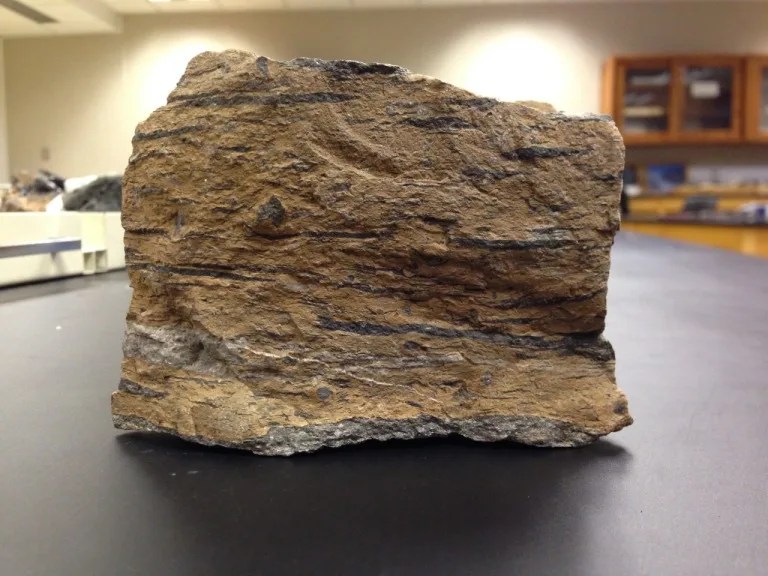

www.customwheeloffset.com  geologyscience.com

geologyscience.com  www.desertcart.in

www.desertcart.in  stownest.com

stownest.com  mystorage.ca

mystorage.ca  www.walmart.com ```html

www.walmart.com ```html